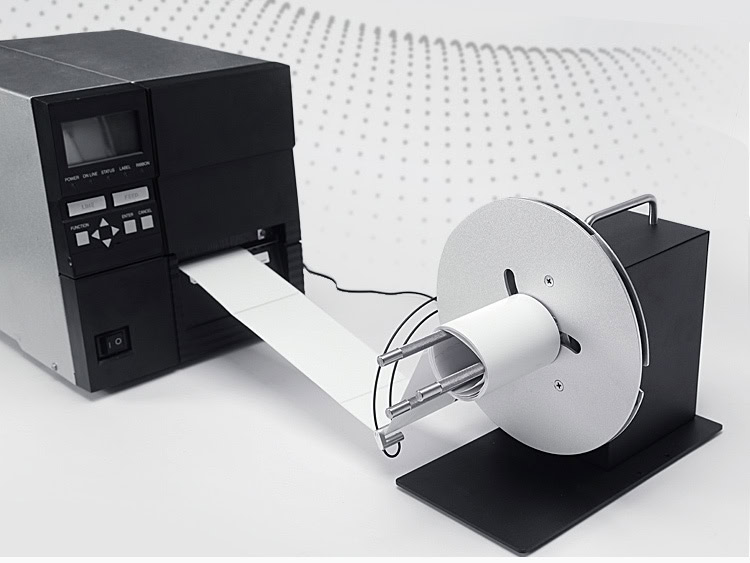

Efficient label management is essential for businesses printing large volumes of labels. PrimeTech Global’s adjustable core Label Rewinders, the R9 and R9+, are built to optimise high-speed label printing.

Label rewinders and unwinders guide labels into printers and neatly wind them into rolls as they exit, minimising manual handling and reducing downtime

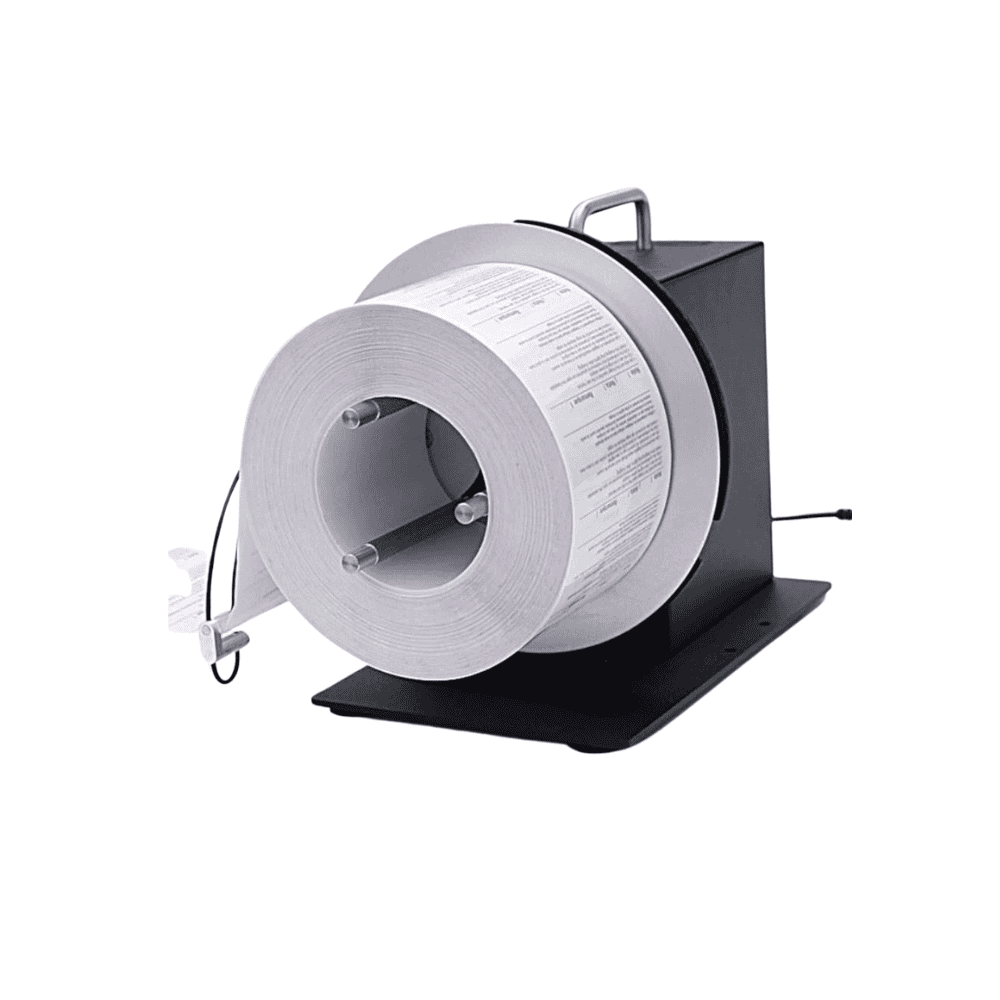

By keeping labels untangled and intact, the R9 and R9+ rewinders and unwinders support smooth label application and consistent print quality. With adjustable cores and automatic synchronisation, they fit perfectly into the needs of food packaging, pharmaceuticals, logistics, retail, and other industries.

What are Label Rewinders and Unwinders?

Label rewinders and unwinders automate the handling of labels.

Label unwinders feed blank labels into the printer, for a smooth and consistent supply.

On the other hand a label rewinder automatically rolls up printed labels into a neat, organised roll after they exit a printer.

Together, they automate label handling, eliminate manual tasks, reduce errors, and support continuous, unattended printing. By efficiently managing both blank and printed labels, these devices keep production lines running smoothly and are essential to labelling systems.

Let’s look at how label unwinders and rewinders improve labelling operations.

Time Savings

One of the primary benefits of label rewinders and unwinders is the substantial time savings they provide:

- Automated rewinding can reduce 20-30 minutes of manual label rolling to just a couple of minutes.

- They eliminate the need for an operator to standby during printing, freeing up workers for other tasks.

- Continuous printing is enabled, allowing for uninterrupted production runs.

Reduced Waste and Improved Organisation

Label rewinders and unwinders help minimise waste and keep labels neatly organised:

- They prevent folded, twisted, or damaged labels that can occur with manual handling.

- Labels are accurately rewound into neat rolls, avoiding unruly heaps of printed labels.

- This organisation is especially beneficial for large volume printing operations.

Higher Production Capacity

These devices enable increased production capacity in several ways:

- They facilitate roll-to-roll printing for greater efficiency.

- Larger roll diameters can be used, reducing the frequency of roll changes and associated downtime.

- Industrial printers with built-in rewinders often have faster print speeds and longer duty cycles.

Flexibility and Control

Label rewinders and unwinders offer greater flexibility in labelling operations:

- They allow for flexible adjustment of roll size for printers printing different roll diameters and width.

- Users can produce preprinted labels in-house, ensuring on-demand availability and reducing reliance on external suppliers.

- They enable centralised printing with distribution of rewound label rolls to different locations within a facility.

Cost Efficiency

While the initial investment in label rewinders and unwinders can be significant, they offer long-term cost benefits:

- Reduced labour costs due to less time spent on manual label handling.

- Less label waste due to damaged or contaminated labels.

- The use of larger rolls can reduce the cost per label.

Overview of PrimeTech Global Label Rewinder R9 and R9+

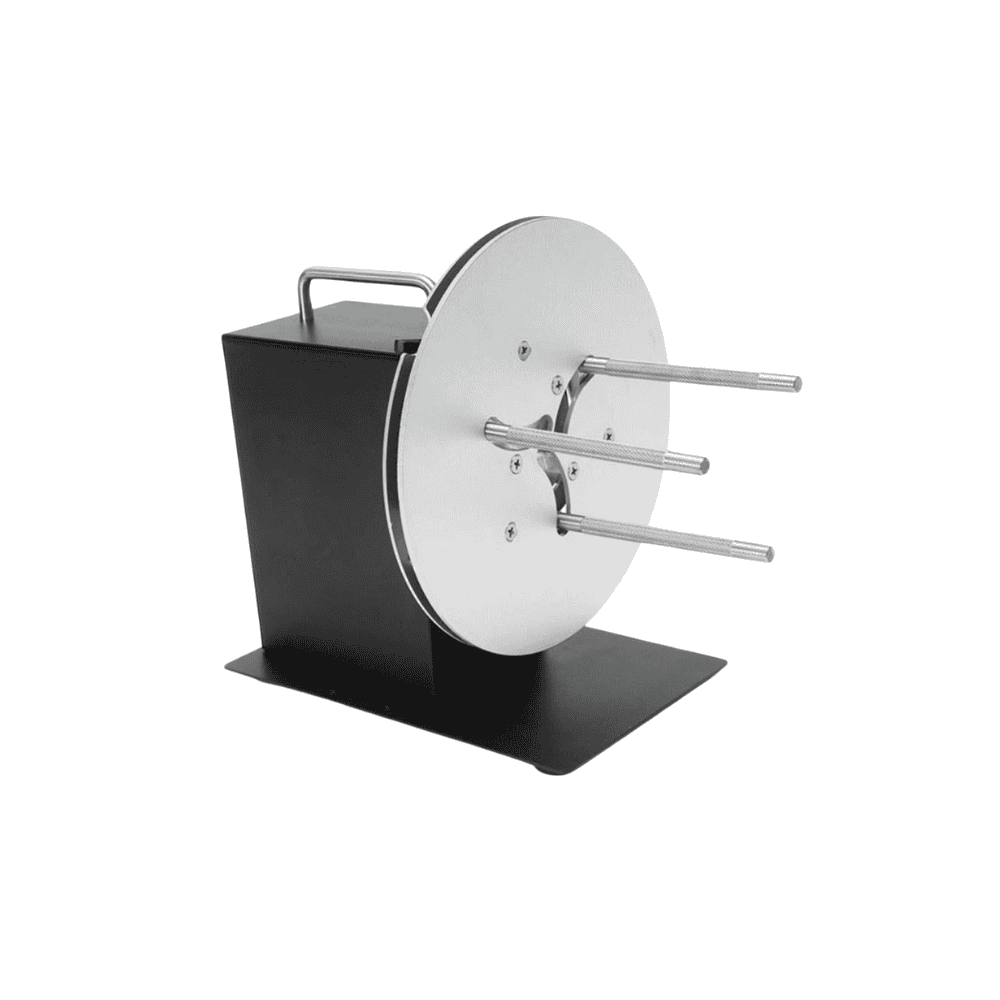

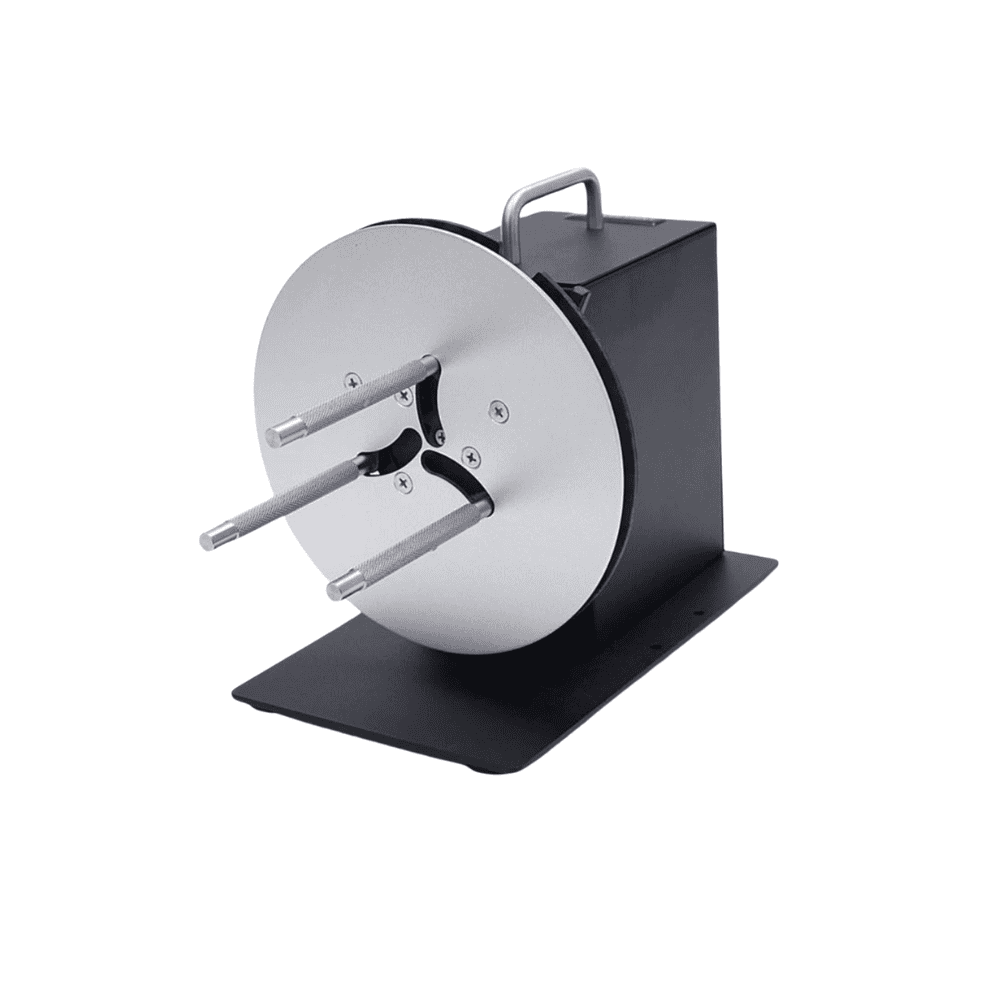

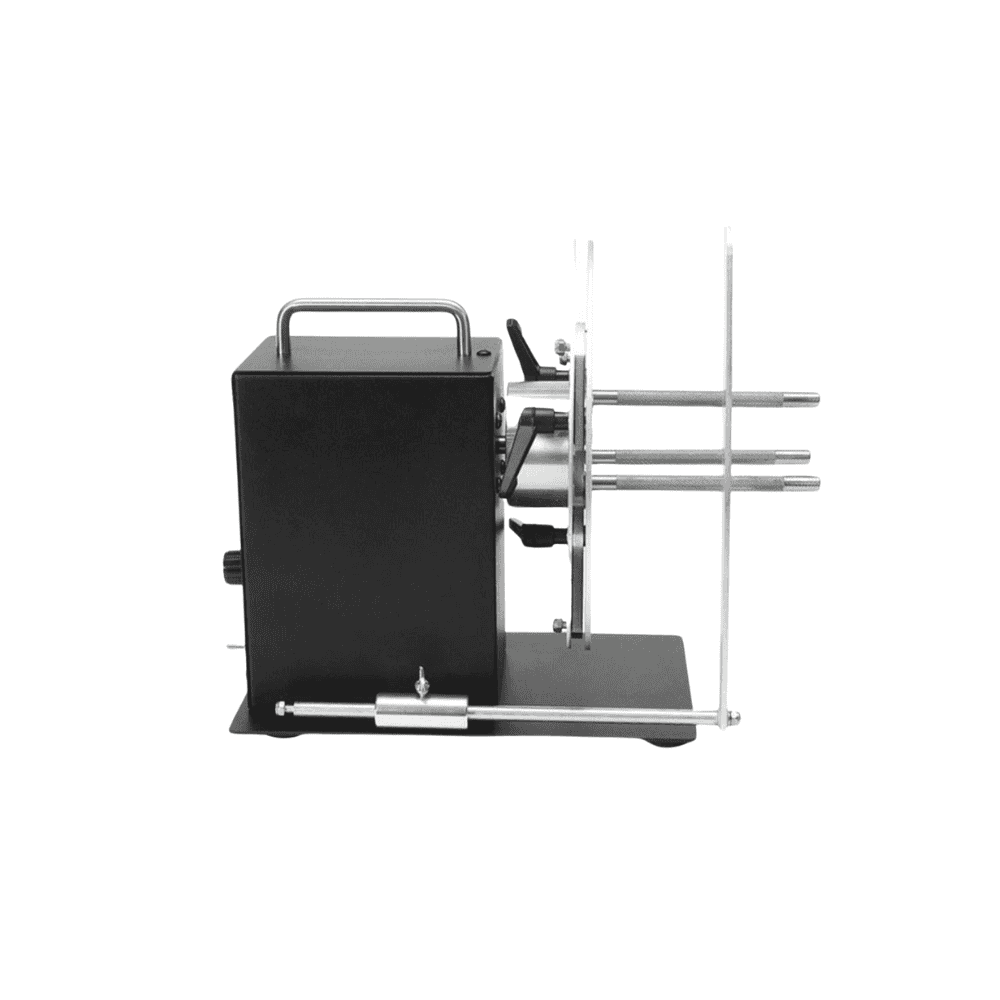

PrimeTech Global’s Label Rewinder R9 and R9+ are designed for optimised high-speed labelling processes. Both models feature adjustable core sizes, allowing users to handle different roll diameters as per specific labelling requirements. They offer a rewinding speed of 12 inches per second, ensuring efficiency in high-volume operations.

The R9 model is suitable for labels with a width of up to 120 mm, while the R9+ can accommodate wider labels up to 150 mm. Both models are equipped with automatic synchronisation technology that adjusts to the printer speed to avoid label jams or tearing. The power consumption for the R9 is 8W, whereas the R9+ requires 10W, offering an energy-efficient solution for industrial needs.

In terms of physical specifications, both models have a disk diameter of 220 mm and are compatible with a wide voltage range (100-240V), allowing for global versatility. The packing size for both is 415 mm x 320 mm x 320 mm, making them compact enough for easy placement in any workspace. The R9 weighs 6 kg, whereas the R9+ weighs slightly more at 6.5 kg, reflecting their capacity differences.

These rewinders are designed with ease of use and adaptability in mind, ensuring they fit into diverse industrial environments where consistent and reliable labelling is a priority. They ensure high-quality label handling and help maintain the consistency and reliability needed for industrial-scale labelling tasks.

Detailed Technical Specification of R9 and R9+ Label Unwinder and Rewinder

The main difference between the two models is that the R9 can handle labels up to 120 mm, whereas the R9+ accommodates up to 150 mm. This difference matters in industries like the beverage industry. For instance breweries using larger bottles need wider labels, making the R9+ ideal for them.

Model | R9 | R9+ |

|---|---|---|

Speed(in/s) | 12 | 12 |

Disk diameter(mm) | 220 | 220 |

Core range(in) | 1-4 | 1-4 |

Label width(mm) | 120 | 150 |

Rewinding method

(automatic synchronisation)

| Positive and negative/pulling force | Positive and negative/pulling force |

Power(W) | 8 | 10 |

Voltage(Power adapter) | 100-240V | 100-240V |

Packing size(mm) | 415*320*320 | 415*320*320 |

G.W(kg) | 6 | 6.5 |

Working environment

(No condensation)

| ‘-20~80℃ | ‘-20~80℃ |

Conclusion

Equip your customers with PrimeTech Global’s R9 and R9+ Label Rewinders. Built for industries like food packaging, pharmaceuticals, and logistics, these machines streamline labelling, save time, and enhance your product line with efficient solutions for your clients.

Contact us at 1300 159 299 or visit the Label Rewinders, Unwinders category page.